Biscuit Package Automatic Sorting Check Weigher/ Checking Weigher with Rejector

Shanghai Tandy Machinery Manufacturing Co., Ltd.- Accuracy:<±0.5g

- Check Weight Range:1-999g

- Application Area:Non-standard Automation System

- Type:Wide-range Series

- Touch Screen:Touch Screen

- Sorting Method:Pusher-bar

Base Info

- Model NO.:TDX-1KG

- Transport Package:Wooden Case

- Specification:1kg

- Trademark:TANDY

- Origin:Shanghai China

- HS Code:8423

- Production Capacity:60PCS,Month

Description

Model no.

Weight scope(g)

Sorting accuracy(g)

Sorting speed /min

Min graduation(g)

Dimension(mm)

Weight(kg)

TDX-100G

3-100

±0.5

60

0.1

1350*640*1420

135

TDX-300G

5-300

±0.5

50-60

0.1

1350*640*1420

160

TDX-1000G

10-1000

±1.0

40-50

0.1

1350*640*1420

205

TDX-3KG

30-3000

±1.5

30-40

1.0

1350*800*1420

260

TDX-25KG

3000-25000

±5.0

10-20

10

1550*1000*1420

300

Pls feel free to contact us if you need more technical parameters!

FAQ:

1. Manufacturer or trading company : Manufacturer

2. Location : Songjiang district , Shanghai

3. Selling markets: Euope , American , Australia , Asia , Africa

4. Customized: Available for customized designs

5. Delivery time: 15 - 30days

6. Warranty period: 1 year

Features of automatic check weigher

1. Precison accuracy

Put to use high speed weighting module of importation and weight sensor in order to ensure checking accuracy.

2. Simple structure

Full stainless steel manufacture, simply structure, easy maintain & maintenrance, according with GMP & HACCP standard.

3. Covenient operation

Adopting brand touch screen, operating simply, displaying intuitively, supporting multi-language (acquiesce in Chinese & English ).

4. Extenal connecting conveniently

Can be connected with other equipment in production line,such as printer, labeller & inkjet printer and so on (client customization).

5. Wide application

Application for bag, filling pack weight checking, there are various rejection way to select (pulling, blowing,pushing jar type and so on ).

6. Function of utomatic feedback

Providing the signal to frontend, feedback packing accuracy in time in order to adjust the feeding status of connected equipment.

Our exhibition:

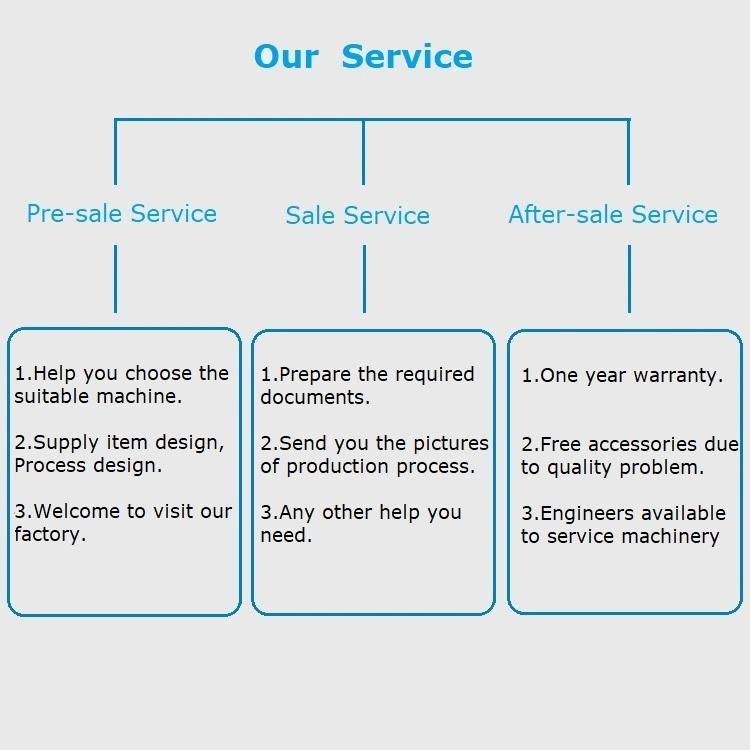

Our service: