Rb Work Ring Gauge on Sale

Xi'an TianRui Petroleum Machinery Equipment Co., Ltd.- Type:Gauge Block

- Measurement Object:Outside Diameter

- Test Methods:Indicator Method

- Material:Steel

- Precision Gauge:Precision Gauge

- Certification:ISO, RoHS, CE

Base Info

- Model NO.:RB1,2 RB3,4 RB1

- Usage:For Working, For Inspection, For Checking

- Shape:Round

- Customized:Non-Customized

- Transport Package:Carton or Wooden Case

- Specification:RB1,8 RB1,4

- Trademark:TR Solids Control

- Origin:Xi′ an, China

- HS Code:84749000

- Production Capacity:10000PCS,Month

Description

Basic Info.

Model NO. RB1/2 RB3/4 RB1 Usage For Working, For Inspection, For Checking Shape Round Customized Non-Customized Transport Package Carton or Wooden Case Specification RB1/8 RB1/4 Trademark TR Solids Control Origin Xi′ an, China HS Code 84749000 Production Capacity 10000PCS/MonthProduct Description

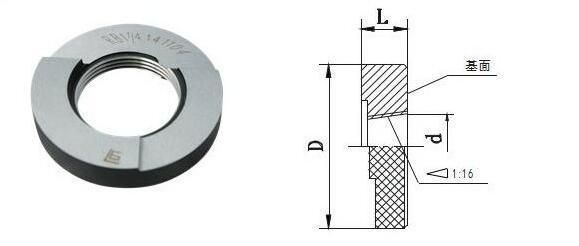

RB Work Ring Gauge

Features

Suitable for checking the taper male thread(thread-seal fittings).It conforms to JB/T10031-1999.

Specifications

Unit:mm

| Thread Size | T.P.I | L | D | d |

| RB1/2 | 14 | 9.979 | 45 | 18.875 |

| RB3/4 | 14 | 11.339 | 48 | 24.361 |

| RB1 | 11 | 12.700 | 56 | 30.608 |

| RB1 1/4 | 11 | 15.009 | 72 | 39.269 |

| RB1 1/2 | 11 | 15.009 | 80 | 45.162 |

| RB2 | 11 | 18.184 | 90 | 56.973 |

| RB2 1/2 | 11 | 20.926 | 115 | 72.537 |

| RB3 | 11 | 24.101 | 135 | 85.237 |

| RB3 1/2 | 11 | 25.663 | 155 | 85.237 |

| RB4 | 11 | 28.864 | 175 | 110.383 |

| RB5 | 11 | 32.039 | 200 | 135.783 |

| RB6 | 11 | 32.039 | 235 | 161.183 |

Features

Suitable for checking the taper female and cylinder female thread.The standard conforms to JB/T10031-1999.

Specifications

Unit:mm

| Thread Size | T.P.I | L1 | L2 | D |

| RB1/8 | 28 | 3.969 | 6.69 | 9.594 |

| RB1/4 | 19 | 6.016 | 10.03 | 12.959 |

| RB 3/8 | 19 | 6.350 | 10.03 | 16.464 |

| RB1/2 | 14 | 8.164 | 13.6 | 20.687 |

| RB3/4 | 14 | 9.525 | 15.0 | 26.173 |

| RB1 | 11 | 10.391 | 17.3 | 32.908 |

| RB1 1/4 | 11 | 12.700 | 19.6 | 41.569 |

| RB1 1/2 | 11 | 12.700 | 19.6 | 47.462 |

| RB2 | 11 | 15.875 | 22.8 | 59.273 |

| RB2 1/2 | 11 | 17.463 | 24.4 | 74.843 |

| RB3 | 11 | 20.638 | 27.6 | 87.543 |

| RB3 1/2 | 11 | 22.20 | 29.1 | 99.989 |

| RB4 | 11 | 25.401 | 32.3 | 112.689 |

| RB5 | 11 | 28.576 | 35.5 | 138.089 |

| RB6 | 11 | 28.576 | 35.5 | 163.489 |

Why Choose Us

1) Experience in casting for over 15 years and served customers all around the world.

2) Standard material according to technical drawing

3)Stable quality

4) On-time delivery

5) Competitive price and good service

6) Positive customer feedback from domestic and international market

7) International advanced-level equipment such as CNC, numerical lathes, furnance, welding

equipment, CMM and detect &testing equipment we used to ensure our product's quality.

8) OEM service, your demand is our pursued.

9) ISO9001:2008 and TS16949 quality control

10) Standard: ASTM BS DIN etc

FAQ

1. What are the main materials of your products?

We are focused on casting and processing of grey iron and ductile iron products.

2. What is your MOQ?

We will arrange production based on your drawings and deliver your products as per your requirements. We will do our best to meet your demands.

3. What is your main equipment?

Our casting equipment is brought from Japan. They mainly include: FBO auto molding lines, sand lines, cleaning lines, vertical and horizontal machining centers and CNC machining center.

4. Do you make the molds by yourself?

We are facilitated with advanced mold making equipment and CNC processing machining center. Therefore, we can make molds independently.

5. What are your advantages?

1) Professional staff

2) 24 years of casting experience

3) Rigorous quality control system

4) On-time delivery rate is over 98%